Madness rules in my workshop right now. I can never start a big project without cleaning up first – even if the workshop is already clean – it’s a Libran thing. I procrastinate for weeks and then finally I know I’m ready when I start cleaning and rearranging things. I’ve given in to it over the years – progress can’t be rushed.

Last weekend about 40 hours of it was spent rearranging the workshop, cleaning tools, putting up new racking and sorting the three bikes I have in pieces on to the their own shelves so I can sort of see them next to each other. I have the 200 EXC and the new 350 EXC-F on the stands at the moment – they both briefly had wheels on them too. Albeit they were both borrowed (wheels) and were put on temporarily to help me clean and rearrange.

In the way of these things I’ve now got multiple jobs on the go at once as parts availability (or non-availability) has brought a temporary halt to progress on one bike or another. So this weekend I have the Husky FE350 motor open with a new piston kit to go in. I’ve also been installing the steering head bearings into the Husky’s repainted frame. And I’ve also made a makeshift spray booth to finish off the parts that I have prepped for painting myself – from all three bikes. So I have parts hanging from beams on wire hooks all around the workshop. And since the Husky’s swingarm is currently in the ‘spray booth’ I will progress to installing the new factory triple clamps onto the frame.

By the way, I’ve been applying a pretty trick stainless steel paint to the parts. Downside is it takes about 10 days to cure, but on the upside this stuff can be welded afterwards it’s so strong (although you might well ask what I might want to weld onto the swingarm… good question). Anyway, more about that in the reveal when the bike’s finished.

Job escalation is another fact of workshop life. Such as when you start one modification only to realise that the aftermarket part you just added may not, or rather definitely is not compatible with another. I made a rookie ‘kid in a sweet shop’ error by rushing out and buying some fancy X-Trig triple clamps for the EXC-F before realising that Scott’s Performance don’t make a steering damper bracket to fit them – argh! As well, apparently Scott’s dampers are no longer a PowerParts item from KTM so when I sent KTM the ‘how to measure and match your clamps’ guide from Scott’s they couldn’t help me either.

Scott’s don’t have the measurements either so I’m onto a big loser here. So if anyone has had the good fortune of receiving a KTM factory triple clamp for Christmas (for their 2020 350 EXC-F) then please contact us – I would dearly love to be able to ascertain if a damper will fit before buying one. Nothing worse than landing up with two sets of very expensive triple clamps in the garage which won’t accept a damper…

In the meantime I’ve been calling KTM dealers to see if anyone has a factory triple clamp in stock and would be willing to take the measurements for me. Yep, rebuilds always throw you a time-consuming curve ball. Thankfully most of the parts of the parts for the 350 EXC-F are here now. The strangest thing is that the parts from the USA seem to arrive at the workshop either as quick if not quicker that then parts from the UK – huh?

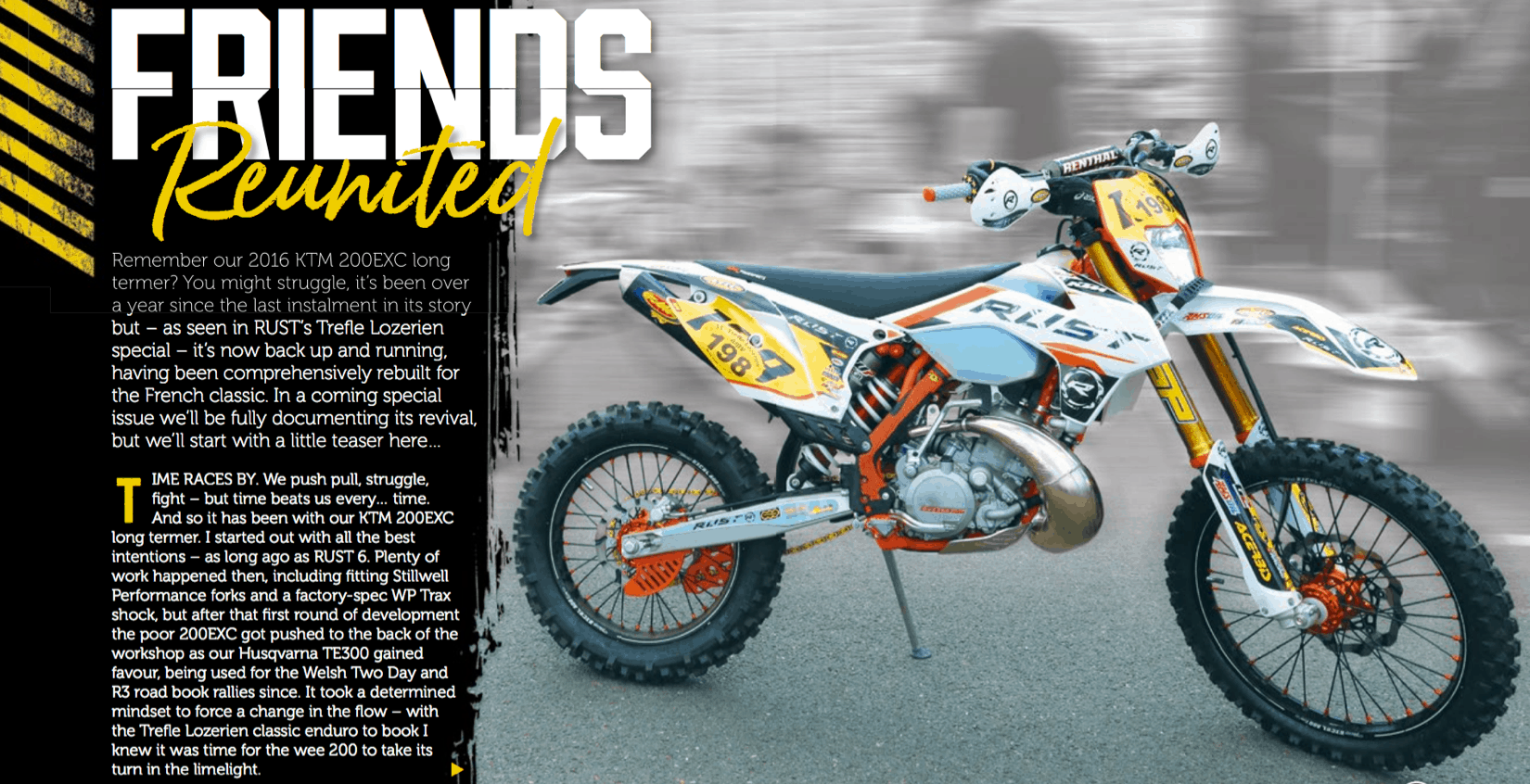

Meanwhile the 2016 200 EXC has come off display (where it has been for the past three years) and has over the past 10 days been rebuilt with the help of my son who is home from Uni for the holidays. We replaced all the bearings, engine gaskets, top end, rebuilt new wheel sets, fitted new mousses and tyres (son’s first time using a Rabaconda – he was pretty good to be fair) added a new air filter and a trick new Acerbis X seat, new controls etc.

I was hoping to get out and ride this with him as a reward for his hard work but as luck would have it we have one single part that perished from lack of use – in the carburettor. The bike is otherwise totally ready, but it floods each time you turn the fuel cock on. So the 200 will again stand, looking pretty, in the far corner of the workshop while I wait for the part to arrive.

The FE 350 meanwhile will remain on workshop bench for at least a week while we finish the motor, bolt it into the frame, attach the subframe and swinging arm and transition it to the stand. It’s a funny thing, I could leave the 200 on the stand for a few more days yet while I prep the FE but somehow the empty stand tells me I’ve finished the 200 and it’s eagerly awaiting its next occupant – no pressure.

I’m now at the end of my word count so time to end. This is the third time I have rebuilt the FE 350, I know this bike really well and I know I have all the compatible parts for it too, so there are likely to be no nasty time delays. I’m nervous though. It’s the first time I have ever stripped the bike to this extent so when it comes to reinstalling the wiring harness I only hope that my labelling when I took it apart is up to scratch, or me standing scratching my head could be the longest delay of all. My first race for 2021 is in 30 days so at least I have time… I think.